Durable Mineral Insulated Heating Cable Ensures Reliable Temperature Control in Harsh Environments

Aug 01,2025

Aug 01,2025

Suke

Suke

In industries where extreme temperatures and harsh environmental conditions are the norm, maintaining reliable temperature control is not just a matter of efficiency—it’s a necessity for safety and operational continuity. The Durable Mineral Insulated Heating Cable has emerged as a groundbreaking solution, designed to withstand the most demanding conditions while ensuring consistent performance. This innovative technology is engineered to provide precise and dependable heat tracing, making it indispensable in sectors such as oil and gas, chemical processing, and power generation. By leveraging advanced materials and robust construction, this heating cable offers unparalleled durability and efficiency, even in the face of corrosive substances, high pressures, and fluctuating temperatures.

The importance of reliable temperature control cannot be overstated, especially in environments where equipment failure or temperature deviations can lead to catastrophic consequences. Traditional heating solutions often fall short in such scenarios, succumbing to wear and tear or failing to deliver consistent heat distribution. The Durable Mineral Insulated Heating Cable addresses these challenges head-on, combining cutting-edge engineering with proven insulation techniques. As we delve deeper into its features and benefits, it becomes clear why this technology is rapidly becoming the gold standard for industries operating under extreme conditions.

Superior Durability in Extreme Conditions

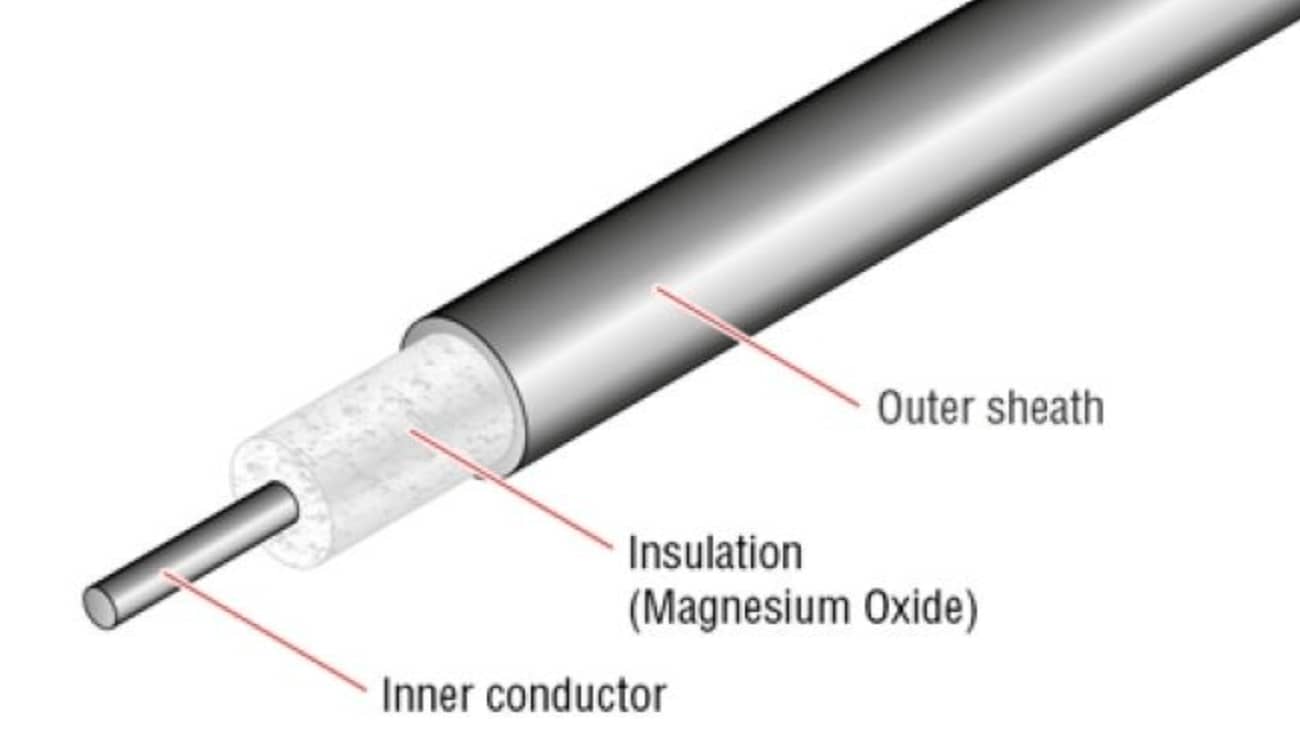

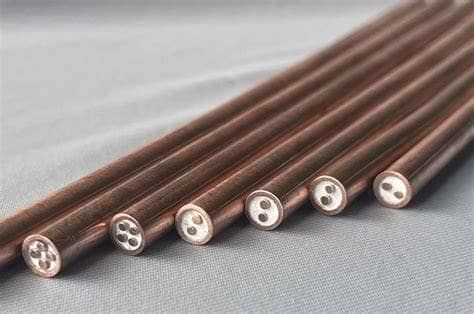

One of the standout features of the Durable Mineral Insulated Heating Cable is its exceptional durability. Constructed with a mineral-insulated core, this cable is inherently resistant to a wide range of environmental stressors. Whether exposed to extreme heat, sub-zero temperatures, or corrosive chemicals, the cable maintains its structural integrity and performance. The mineral insulation not only provides excellent thermal conductivity but also acts as a barrier against moisture and other corrosive elements, ensuring long-term reliability.

Moreover, the outer sheath of the cable is typically made from high-grade stainless steel or other corrosion-resistant alloys, further enhancing its ability to withstand harsh conditions. This combination of materials makes the cable ideal for use in offshore platforms, refineries, and other industrial settings where exposure to saltwater, acids, and abrasive materials is common. Unlike conventional heating cables that may degrade over time, the Durable Mineral Insulated Heating Cable is built to last, reducing the need for frequent replacements and minimizing downtime.

Precise and Consistent Temperature Control

Another critical advantage of this heating cable is its ability to deliver precise and consistent temperature control. The mineral-insulated design ensures uniform heat distribution along the entire length of the cable, eliminating hot spots or cold zones that can compromise system performance. This level of precision is particularly vital in processes where maintaining a specific temperature range is crucial, such as in pipeline heating or freeze protection.

Advanced control systems can be integrated with the heating cable to monitor and adjust temperatures in real-time, providing an additional layer of reliability. These systems can detect fluctuations and automatically compensate, ensuring that the desired temperature is maintained without manual intervention. This feature is especially valuable in remote or hard-to-access locations, where constant monitoring may not be feasible. By combining robust construction with smart technology, the Durable Mineral Insulated Heating Cable offers a level of control that is unmatched by traditional solutions.

Energy Efficiency and Cost Savings

In addition to its durability and precision, the Durable Mineral Insulated Heating Cable is also highly energy-efficient. The mineral insulation not only enhances thermal performance but also minimizes heat loss, ensuring that energy is used effectively. This efficiency translates into significant cost savings over time, as less energy is required to maintain the desired temperature compared to conventional heating methods.

Furthermore, the longevity of the cable reduces maintenance and replacement costs, contributing to lower total cost of ownership. Industries that adopt this technology can expect a rapid return on investment, thanks to reduced energy consumption and fewer operational interruptions. In an era where sustainability and cost-effectiveness are paramount, the Durable Mineral Insulated Heating Cable stands out as a smart choice for forward-thinking organizations.

Versatility Across Industries

The applications of the Durable Mineral Insulated Heating Cable are as diverse as the industries it serves. In the oil and gas sector, it is used for pipeline heating, tank heating, and freeze protection, ensuring smooth operations in some of the harshest environments on Earth. Chemical processing plants rely on it to maintain optimal temperatures for sensitive reactions, while power generation facilities use it to prevent ice buildup on critical infrastructure.

Beyond heavy industry, this heating cable is also employed in commercial and residential settings for underfloor heating and snow melting systems. Its versatility stems from its ability to be customized to meet specific requirements, such as varying lengths, wattages, and sheath materials. This adaptability makes it a go-to solution for a wide range of temperature control challenges, further solidifying its reputation as a reliable and flexible technology.

In conclusion, the Durable Mineral Insulated Heating Cable represents a significant advancement in temperature control technology. Its unmatched durability, precision, energy efficiency, and versatility make it an indispensable tool for industries operating in harsh environments. As demands for reliable and sustainable solutions continue to grow, this heating cable is poised to play an increasingly vital role in ensuring operational success across multiple sectors.

Home

Home Suke Fireproof Electrical Wire Factory Company | Safe Wiring Solutions for Home & Office

Suke Fireproof Electrical Wire Factory Company | Safe Wiring Solutions for Home & Office  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address